WEMALO Features

Optimise production processes with WEMALO

Production processes should be as efficient as possible. WEMALO offers you the ideal solution for seamlessly connecting all processes from warehousing to manufacturing.

Production must be well planned

Is a lack of transparency and the resulting inefficient production hindering processes?

In today’s production environment, it is crucial that all processes run efficiently and transparently. Nevertheless, many companies struggle with typical challenges: a lack of real-time information about inventory levels, manual processes that are prone to errors, and a lack of integration between production and warehouse management. These problems often lead to delays in production, inefficient resource planning and ultimately higher costs. Especially in times when flexibility and speed are crucial to competitiveness, suboptimal production management can seriously jeopardise your growth.

Smooth processes

WEMALO optimises production processes

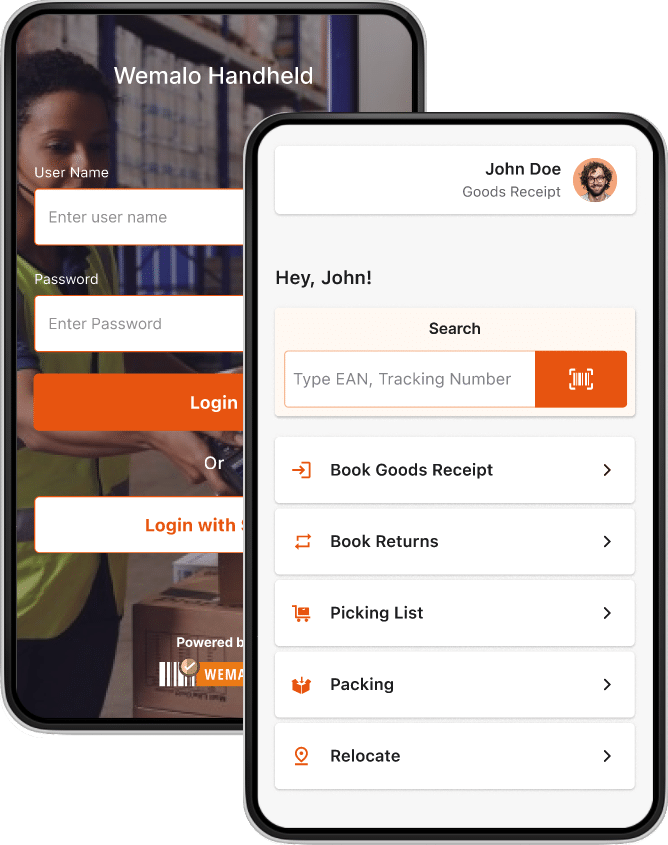

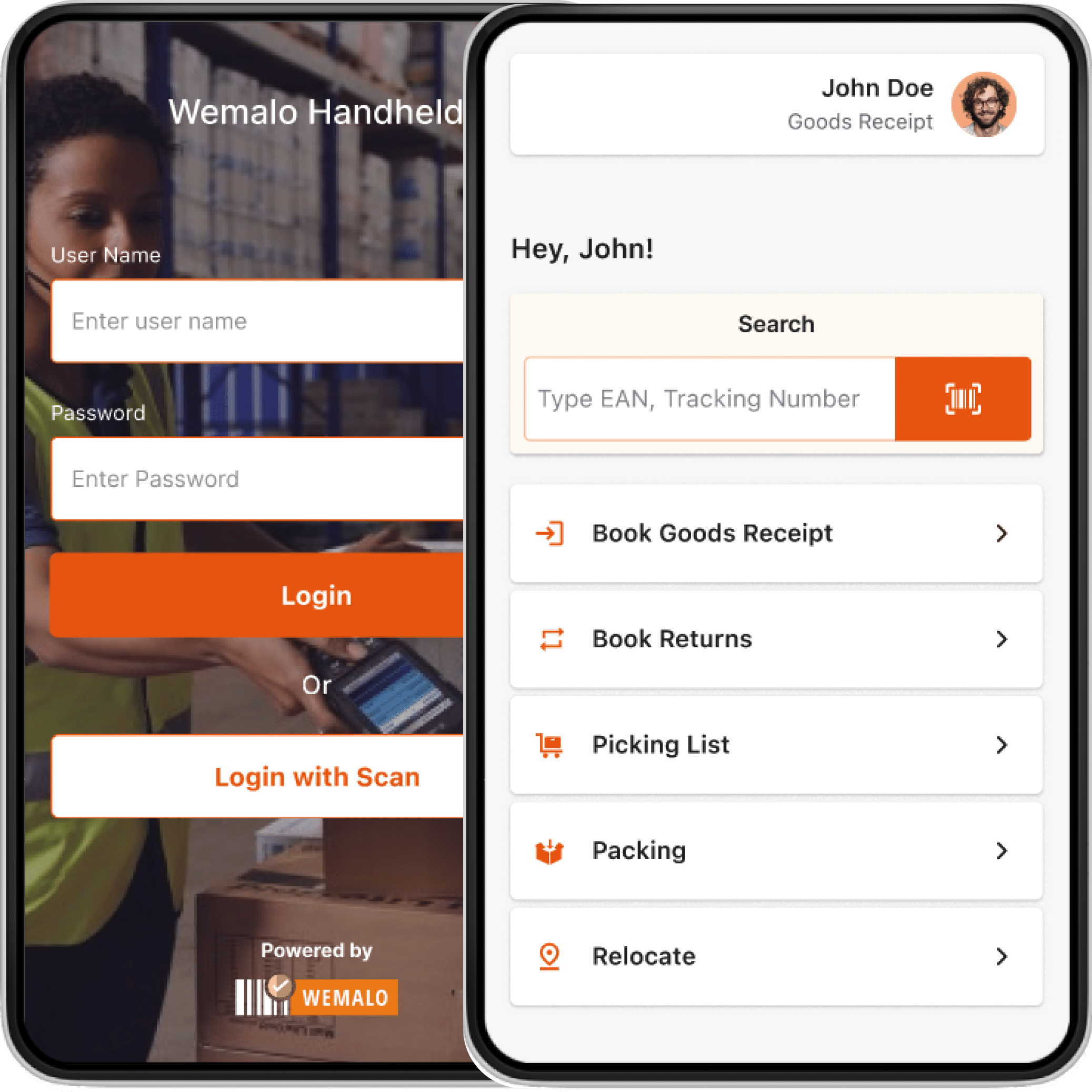

With WEMALO, chaos in production planning is a thing of the past. Our comprehensive warehouse management software allows you to keep track of all relevant information at all times, enabling you to precisely control the production of goods. Special functions such as marking production-relevant items, creating and managing production orders, and seamless production execution optimise the entire process.

WEMALO offers the following functions for your warehouse production

Mark products as relevant to production

With WEMALO, you can mark specific items in your warehouse as relevant to production. This ensures that only the necessary components are provided for production, which optimises your material flow planning and avoids bottlenecks.

Creating production orders

Our software enables you to create production orders with precision. Whether you are manufacturing individual components or complex products, WEMALO supports you with a clear overview and complete traceability.

Production implementation

Once all materials are ready, WEMALO guides you through the production process. Our software controls all the necessary work steps and ensures that each step runs smoothly. From picking the raw materials to the final picking of the finished products – every step is planned and documented in detail.

Picking

A key element of the production process is the efficient picking of the right materials. With WEMALO, the process becomes child’s play. The software enables materials and components to be picked precisely and in the correct order, allowing production processes to continue without delays.

From practice

How we use WEMALO

Our many years of experience in warehouse logistics have shown us how important it is to seamlessly integrate warehouse management and production. We use WEMALO every day in our own warehouses to ensure maximum efficiency. By clearly labelling production-related products and automating production orders, we are able to ensure uninterrupted production flow. Thanks to the precise pick-and-pack functions, the necessary components are assembled in no time and forwarded directly to production.

For example, in one of our warehouses for electronic components, we were able to reduce production times by 25% by using WEMALO to speed up the process from warehouse receipt to finished end product. Employees benefit from a simple interface that allows them to quickly find and process all production orders and the associated materials. This prevents bottlenecks and ensures that product quality remains consistently high.

By using our software, we were not only able to save time, but also significantly reduce the error rate. Seamless coordination between production and warehouse management allows us to identify bottlenecks early on and take proactive action.

Find out how you too can optimise your warehouse processes with WEMALO!

Request an online presentation and arrange an appointment with us! We are happy to advise you.

Free and without obligation!