Stock management software for small businesses: Optimise your warehouse management with efficient solutions

With functions such as inventory management, accounting and mobile access on your system or as an app download, products and items are easy to manage.

Warehouse management made easy: Efficient solutions for small businesses to optimise your warehouse processes. Warehouse management software

The topics to help you get started quickly on the site:

Advantages of warehouse management software for small businesses

Stock management software offers small businesses a number of advantages over manual warehouse management. We will look at these advantages in more detail below:

10 advantages that the use of warehouse management software offers companies:

- Accuracy of stock levels: Warehouse management software ensures accurate recording and updating of stock levels in real time, resulting in improved stock control.

- Error reduction: By using warehouse management software, manual errors when recording stock movements can be minimised, resulting in greater data integrity.

- Optimisation of space requirements: The software enables efficient use of storage space as it accurately records inventory data and suggests the optimum storage space allocation.

- Improved order processing: Warehouse management software enables faster and error-free order processing by synchronising inventory data with order information to ensure a smooth workflow.

- Reducing operating costs: By utilising resources efficiently, reducing stock levels and avoiding excess stock, the warehouse management software helps to reduce costs.

- Time savings: Automated processes and workflows enable faster processing of stock movements, which reduces overall operating time and increases efficiency.

- Improved delivery time: By optimising warehouse processes and providing quick access to inventory data, warehouse management software can improve delivery times to customers.

- Product traceability: The software enables seamless traceability of products from incoming to outgoing goods, which supports quality assurance and product liability.

- Real-time analysis and reporting: Warehouse management software provides the ability to generate real-time reports and analyses on inventory levels, productivity and performance to make informed operational decisions.

- Scalability and flexibility: Good warehouse management software grows with the business and adapts to changing requirements, allowing small businesses to seamlessly expand their warehouse management as the business grows.

Efficient processes thanks to automated warehouse management

All in all, such a solution offers numerous advantages for small businesses in terms of effectiveness and cost savings in the area of logistics processes at their location or even beyond!

Time and cost savings in inventory tracking

Effective inventory tracking is of great importance and a crucial component of successful warehouse management.

Warehouse management software provides real-time updates on current stock levels, enables products to be located quickly and facilitates stocktaking.

This can save small businesses time and money by reducing manual stock counts and avoiding shortages or overstocking.

Optimierung der Lagerplatznutzung für maximale Effizienz

Warehouse management software enables optimal utilisation of the available storage space. It helps to identify storage areas, shows the ideal storage location for certain products and enables optimal placement.

By making better use of storage space, small companies can organise their processes more efficiently and reduce their storage costs. However, it is not only the optimal utilisation of storage space that is an advantage of such software. A better overview of current stock levels and faster and more accurate stocktaking are also possible.

By scanning barcodes or QR codes, products can be easily recorded without errors occurring. The warehouse management software also enables automatic reordering when stocks of certain products are low.

This ensures that there are always enough goods in stock and bottlenecks are avoided. Another plus point: the data on the movement of goods in the warehouse can be called up and analysed in real time.

This makes it possible to recognise trends or identify weak points in the process, for example – valuable information for future decisions.

In short: good warehouse management software helps small companies to improve their processes, save costs and therefore be more successful in the long term!

Auswahl einer Lagerverwaltungssoftware: Darauf sollten Sie achten

Choosing the right warehouse management software is crucial to the success of a small business. Here are some important aspects to consider when choosing warehouse management software:

Determining needs and analysing requirements

Before deciding on warehouse management software, it is important to exactly analyse the needs and requirements of your company. Make sure that the software you choose offers the specific functions and tools you need to manage your warehouse processes efficiently.

Carry out a thorough needs analysis and identify the core functions. Another important consideration when choosing warehouse management software is integration with other systems and applications in your organisation.

Make sure that the software can be seamlessly integrated with your existing ERP or WMS solutions. You should also consider the software provider’s support and service.

Make sure that the company offers reliable customer service and can respond quickly in the event of problems.

Another aspect is the user-friendliness of the software. An intuitive user interface not only makes your work as a user easier, but also reduces training costs for new employees.

Finally, you should consider whether a cloud-based solution could be useful in order to be able to react more flexibly to changes in the market.

All in all, it is worth investing time in a thorough analysis of your specific requirements and comparative research to choose a suitable system – because this saves costs in the long term through more efficient processes!

10 aspects for choosing the right warehouse management software

- Business requirements analysis: Analyse your company’s specific requirements in terms of warehouse management to determine which functions and tools you need.

- Scalability: Ensure that the warehouse management software is scalable and can grow as your business grows.

- Integration with existing systems: Check whether the software can be seamlessly integrated with your existing business systems such as ERP or e-commerce platforms.

- User-friendliness: Make sure the software offers a user-friendly interface and ease of use to ensure employee adoption and efficiency.

- Customer support and training: Check whether the provider offers adequate customer support and training to ensure that you are optimally supported when using the software.

- Mobility: Check whether the warehouse management software can also be used on the move to enable employee flexibility and mobility.

- Reporting and analysis: Make sure the software provides reporting and analysis capabilities to get a comprehensive overview of your warehouse performance.

- Costs and ROI: Compare the costs of different warehouse management software solutions and evaluate the expected return on investment (ROI) to make an informed decision.

- Security: Ask about the provider’s security measures to ensure that your sensitive warehouse data is protected.

- Expandability and adaptability: Check whether the software is expandable and customisable to respond to future requirements.

Warehouse management systems: What solutions are available?

Nowadays, efficient warehouse management is of great importance for companies. There are various systems that can be used to manage and organise the warehouse. Each offers its own advantages and functions. In the following, we will take a look at some of the most common solutions:

The manual warehouse management system

A classic example of this is the manual warehouse management system. Here, stock levels and incoming and outgoing goods are recorded manually in lists or on index cards.

This system has the advantage of lower acquisition and operating costs compared to other methods, but it also harbours a higher risk of data entry errors.

The RFID warehouse management system

The RFID warehouse management system, on the other hand, uses radio technology to read or transmit data. No visual contact is necessary, as is the case with barcode scanners, for example. It is therefore used more frequently when large quantities of goods need to be moved. This system is therefore particularly suitable for larger logistics centres with many items in circulation.

The barcode warehouse management system

Another option is the barcode warehouse management system. Here, each item is labelled with an individual barcode, which is then recorded when it is stored or removed. This allows stock to be taken more quickly than with the manual method.

To summarise, it can be said that each of these three systems has its advantages and disadvantages. Which one is ultimately the most suitable depends primarily on the respective application; for example, a small company with manageable stock levels should opt for the manual method, while a large logistics company should use an RFID system.

Insight into the WMS: The Warehouse Management System

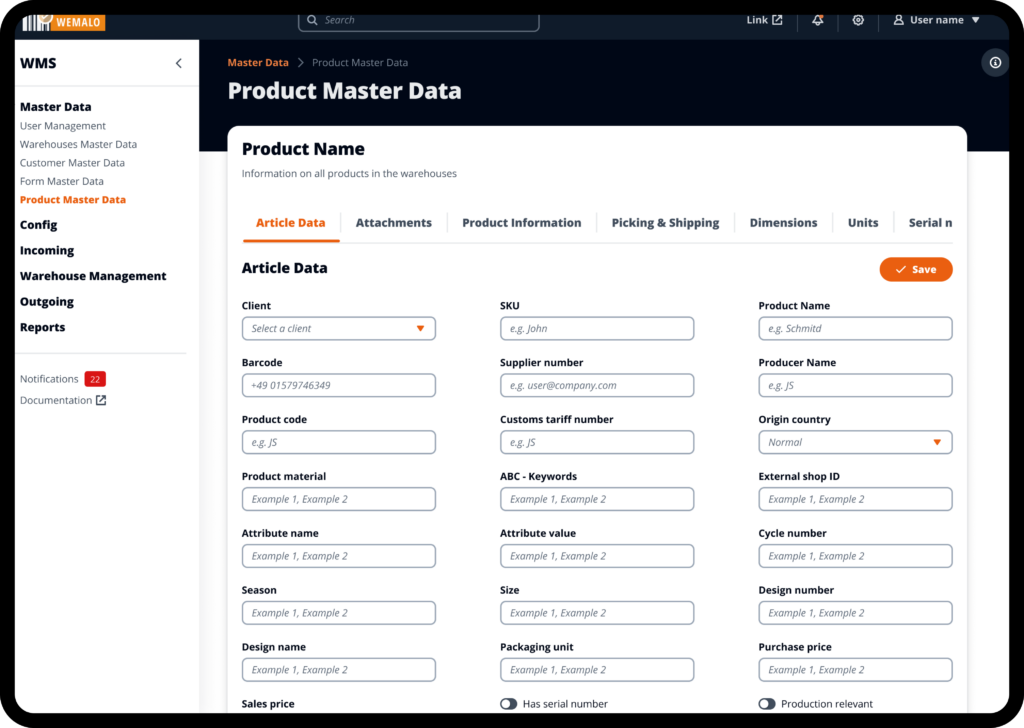

A Warehouse Management System (WMS) is a comprehensive solution for warehouse management. It offers functions such as inventory tracking, putaway, picking, dispatch processing, space optimisation strategies and reporting.

WMS systems can be hosted on local servers or in the cloud and provide a user-friendly interface to monitor and control all aspects of warehouse management.

Thanks to a Warehouse Management System (WMS), warehouse management can be controlled effectively and comprehensively. The system offers numerous functions, such as stock control, storage of goods, picking and dispatch processing.

Strategies for space optimisation can also be developed with the help of the WMS and reports on the current status of stock levels can be called up at any time.

The software can either be installed on a local server or hosted in the cloud – a user-friendly interface provides a quick overview of all relevant aspects of warehouse management at all times.

Functions and advantages of warehouse management systems

Warehouse management systems offer a wide range of functions that cover the entire warehouse operation. Key functions include real-time inventory tracking, picking, tracking of goods received, traceability of goods, FIFO and LIFO management, automatic replenishment and integration with suppliers and carriers.

The benefits of such systems lie in improving the accuracy, efficiency and flexibility of warehouse management. With a warehouse management system, all aspects of the warehouse can be covered.

The functions range from real-time stock tracking and order picking to traceability and FIFO or LIFO management. Automatic replenishment and integration with suppliers and forwarders are also possible. The use of such systems not only significantly improves accuracy, but also efficiency and flexibility in warehousing.

Warehouse management in general. An overview

Efficient warehouse management enables companies to reduce costs, increase productivity and improve customer satisfaction.

Warehouse management includes various tasks such as recording and monitoring stock levels and managing goods movements. Effective warehouse management enables companies to optimise their stock, identify bottlenecks and shorten delivery times. It also offers the opportunity to take into account specific requirements of individual items or customer orders and ensure on-time delivery.

Benefits of efficient warehouse management include real-time updating of stock levels, optimisation of storage location management and precise location tracking of goods. Good warehouse management software with a user-friendly and intuitive interface is crucial for efficient utilisation.

Overall, efficient warehouse management improves operational processes, saves time and costs, increases customer satisfaction and improves competitiveness. When choosing warehouse management software, an intuitive user interface, comprehensive functions and seamless integration with other operational systems are important.

Challenges in manual warehouse management

Manual warehouse management can present numerous challenges. Common problems include inaccurate inventory tracking, loss or damage to goods, inefficient use of space, incorrect order processing and poor communication between employees.

These challenges can lead to increased costs, dissatisfied customers and inefficient warehouse operations. To overcome these challenges, it is advisable to switch to an automated warehouse management system.

FAQs:

Warehouse management software can offer numerous advantages for small companies. Firstly, it enables efficient organisation of the warehouse and helps to keep track of stocks and deliveries.

By automatically recording incoming and outgoing goods, bottlenecks or surpluses can be quickly recognised. Furthermore, such software also makes it easier to create invoices and manage customer and supplier data. This saves time in accounting and minimises sources of error due to manual entries.

In addition, warehouse management software often also offers functions such as barcode recognition or mobile data capture via smartphone or tablet, which in turn helps to increase efficiency.

Overall, it can be said that modern warehouse management is essential, especially for smaller companies with limited staff, in order to optimise processes and save costs. An appropriate software solution can help here – both in terms of time savings and in terms of greater customer satisfaction thanks to the rapid availability of desired products.

First and foremost, good warehouse management software should offer a user-friendly interface that allows the user to access all functions quickly and easily. The following functions should also be available:

- Inventory management: The software should be able to manage the current stock of goods in the warehouse.</li

- Goods receipt/issue management: It must be possible to record incoming deliveries and prepare and process outgoing shipments.

- Batch/serial number tracking: Effective tracking of serial or batch numbers is important for recalls or warranty cases.

- Automated inventory processes: Automated processes can significantly reduce the effort involved in annual stocktaking.

- Create statistics/reports: Meaningful reports are essential to obtain an overview of the current situation of the warehouse

- Compatibility with other systems: Integration with other software systems such as ERP (Enterprise Resource Planning) is becoming increasingly important to ensure smooth operation Overall, there are many factors that must be taken into account in good warehouse management software so that it can act not only as support but also as a criterion for success

- .

There are different types of warehouse management systems that can be used depending on the needs and size of the warehouse.

One option is the manual system, where all stock is noted and managed by hand. However, this can be very time-consuming and carries a higher risk of errors.

Another option is to use computerised systems such as barcode scanners or RFID technology to identify stock in the warehouse. These enable data to be recorded and processed more quickly, thus minimising sources of human error.

For larger companies with extensive incoming and outgoing goods, complex software solutions are available that automate all processes – from storage to dispatch of the products.

Ultimately, the choice of the right system always depends on the individual requirements: How large is the warehouse? How many items need to be recorded? What type of products are to be stored or dispatched?

But no matter which system is chosen – effective warehouse management makes a significant contribution to ensuring that processes run smoothly and costs are saved & customers remain satisfied!

Choosing the right warehouse management software is of great importance for any company that stores and distributes goods. Good software can help you keep track of stock levels, plan deliveries efficiently and avoid errors during stocktaking.

Firstly, you should be clear about which functions your warehouse management needs. For example, do you need an automatic ordering function or a product traceability system? Would you also like to be able to use mobile devices such as handheld scanners?

Another important factor is integration with other business areas such as sales or purchasing. The possibility of seamless collaboration between different departments can save time and optimise processes.

Of course, costs also play a role in the selection of a suitable software solution. However, it is worth looking at more than just the price – cheap solutions are often more expensive in the long term due to a lack of functionality or poor support quality.

Don’t forget to look at reviews from other users and reference projects from the provider to ensure that it has already been used successfully in similar sectors. All in all, take enough time to carefully weigh up the various options before deciding which solution is the best fit!

The implementation of warehouse management software can have numerous positive effects for your company.

Firstly, the software enables more efficient and precise management of your warehouse, resulting in a better overview of your stock. This allows you to identify bottlenecks or surpluses more quickly and act accordingly.

Furthermore, using the software also minimises the risk of errors, as all data is recorded centrally and is therefore standardised. This not only increases the accuracy of your stocktaking, but also saves you time when manually reconciling different lists.

Another advantage is the possibility to optimise your processes in the warehouse area: automated processes such as barcode scanning or automatic reordering can speed up workflows – this in turn increases your efficiency as well as productivity.

Not least, such a software solution often also offers functions for analysing key figures (such as sales development), which provide important information for making decisions regarding purchasing or sales. to be able to make purchasing or sales decisions.

All in all, it can be said that with the help of modern warehouse management software your business will be more competitive in the long run – both in terms of costs and quality!

Conclusion: Efficient warehouse management for small companies

Overall, it can be said that efficient warehouse management is of great importance for small companies. By organising and managing the warehouse correctly, costs can be saved and processes optimised.

It is therefore advisable to introduce or implement a suitable warehouse management system. Attention should be paid to the individual requirements of the company in order to achieve the best possible result.

In addition, the use of modern technologies such as barcode scanners or automatic stock checks can also help to maintain an overview of the inventory and save time on manual activities.

Ultimately, well-organised warehousing not only means that products can be found more quickly, but also increases the overall effectiveness of a small business – which in turn promises long-term success.